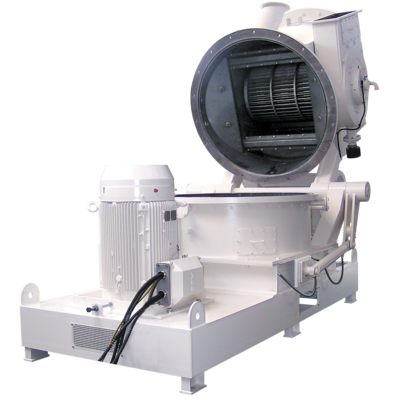

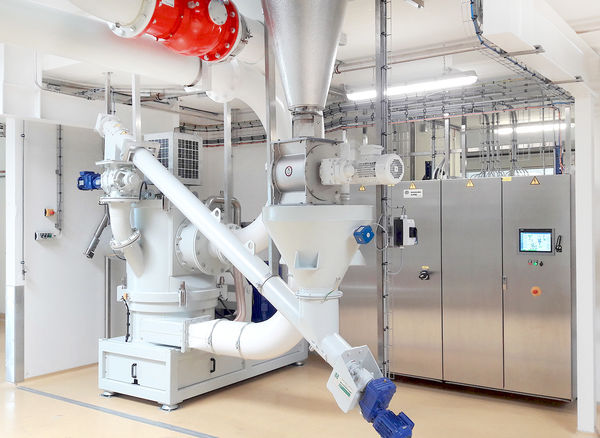

The size-reduction elements comprise an impact beater unit plus a stationary triangular-ribbed grinding track that surrounds the grinding chamber. The impact beater unit is designed such that the grinding process is very efficient. The impact beaters are exchangeable; the grinding track is in segmented design. A Turboplex ultrafine classifier with one or more horizontal classifying wheels is integrated into the top section of the mill.

The feed product, charged to the machine by a system-sided feed unit, enters at the filling socket and is intercepted by the impact beaters on the beater disc. The combined action of the beaters and grinding track serves to comminute the product, which is then transported via the classifier to the fines discharge. The air introduced into the machine at the air inlet cools, transports and also classifies the product in the integrated classifier. Dependent on the specification, the feed product can also be introduced into the machine entrained in the air. The fines, extracted in accordance with the cut point set at the classifier, exit the machine via the fines discharge. The end product must be separated from the air in a downstream system-sided collection unit.