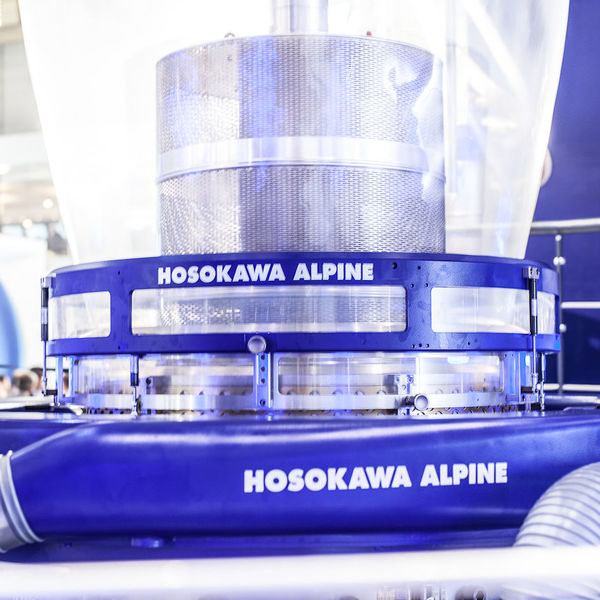

Para procesamiento de sólidos

Recambios y reparaciones

Control de procesos

Remote service

Comprobación de seguridad

Más información

Para instalaciones de película soplada

Recambios y reparaciones

Limpieza del cabezal de soplado

Remote-service/eSupport

Más información

Hosokawa Solids pertenece al Hosokawa Alpine

Tu sólido a granel. Nuestra solución.Tecnología de transporte neumático, pesada y dosificación, así como silos equipados: desde 2020, Hosokawa Solids y sus componentes y sistemas forman parte del grupo Hosokawa Alpine. Ahora también puede encontrar la gama completa de Hosokawa Solids en nuestro sitio web.